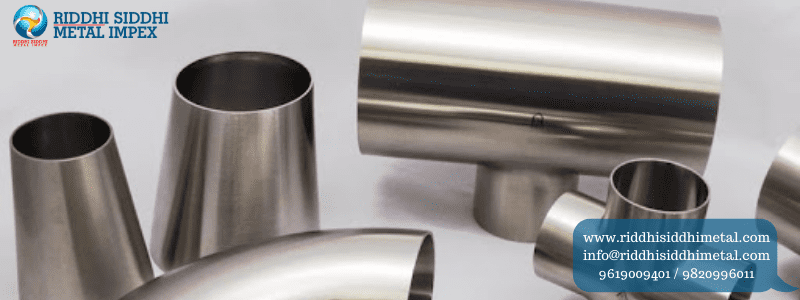

Riddhi Siddhi Metal Impex is one of the leading Alloy Steel Flanges manufacturers in Mumbai, India. Our Products have been designed under the national and international industry rules using high-grade raw materials and advanced technology. Our ASTM A182 F5 Alloy Steel Flanges and other products are subjected to various quality checks, and then goes for packaging. Riddhi Siddhi Metal Impex is the world-leading exporter of Alloy Steel Flanges. We have a ready stock of ASME SA234M Alloy Steel Steel Flanges of different sizes and shapes per the customers’ requirements. We treat our customers as partners by providing them with our products and solutions.

Alloy Steel Buttweld Fittings Manufacturer, Alloy Steel Flanges Supplier, Alloy Steel Gasket Exporter, ASME SA234M Buttweld Fittings Dealer in India

Alloy Steel Flanges is exclusively designed for several piping applications of various industries. We are also known as one of the Largest Suppliers of high-quality Alloy Steel Forged Fittings, Alloy Steel Filteration suppliers, Alloy Steel Filteration, and many more. Alloy Steel Flanges are defined as one of the essential parts of the Pipe Fitting Industry. We are also known as one of the Largest Suppliers of Duplex Steel.

Alloy Steel Grades Chart

| Material | Condition | Yield Strength [ksi] |

Ultimate Strength [ksi] |

Elongation % |

Elastic Modulus [psi] |

Density [lb/in3] |

Poisson’s Ratio |

|---|---|---|---|---|---|---|---|

| AISI 4130 | Hot Rolled | 70 | 90 | 20 | 29e6 | 0.283 | 0.32 |

| Stress Relieved | 85 | 105 | 10 | ||||

| Annealed | 55 | 75 | 30 | ||||

| Normalized | 60 | 90 | 20 | ||||

| AISI 4140 | Hot Rolled | 90 | 120 | 15 | 29.7e6 | 0.283 | 0.32 |

| Stress Relieved | 100 | 120 | 10 | ||||

| Annealed | 60 | 80 | 25 | ||||

| Normalized | 90 | 120 | 20 | ||||

| ASTM A242 | 46 | 67 | 18 | 30e6 | 0.282 | 0.3 | |

| ASTM A302 | Grade A | 45 | 75 | 15 | 29e6 | 0.282 | 0.29 |

| Grade C | 50 | 80 | 17 | ||||

| ASTM A514 | Quenched & Tempered | 100 | 110 | 18 | 29e6 | 0.283 | 0.3 |

| ASTM A517 | Grade F | 100 | 115 | 16 | 29e6 | 0.280 | 0.29 |

| ASTM A533 | Class 1 | 50 | 80 | 18 | 29e6 | 0.282 | 0.29 |

| Class 2 | 70 | 90 | 16 | ||||

| Class 3 | 83 | 100 | 16 | ||||

| ASTM A572 | Grade 50 | 50 | 65 | 18 | 30e6 | 0.283 | 0.3 |

| ASTM A588 | 50 | 70 | 18 | 29.7e6 | 0.280 | 0.28 | |

| ASTM A633 | Grade E | 55 | 75 | 18 | 29.7e6 | 0.280 | 0.28 |

| ASTM A656 | Grade 50 | 50 | 60 | 20 | 29e6 | 0.282 | 0.29 |

| Grade 60 | 60 | 70 | 17 | ||||

| Grade 70 | 70 | 80 | 14 | ||||

| Grade 80 | 80 | 90 | 12 | ||||

| Grade 100 | 100 | 110 | 12 | ||||

| ASTM A710 | Grade A | 80 | 85 | 20 | 29.7e6 | 0.280 | 0.3 |

| HY-80 | 80 | — | 18 | 29.7e6 | 0.280 | 0.3 | |

| HY-100 | 100 | — | 16 | 29.7e6 | 0.284 | 0.3 |

Alloy Steel Chemical Composition Chart

| Element | Content (%) |

|---|---|

| Chromium, Cr | 0.80 – 1.10 |

| Manganese, Mn | 0.75 – 1.0 |

| Carbon, C | 0.380 – 0.430 |

| Silicon, Si | 0.15 – 0.30 |

| Molybdenum, Mo | 0.15 – 0.25 |

| Sulfur, S | 0.040 |

| Phosphorous, P | 0.035 |

| Iron, Fe | Balance |

Alloy Steel Mechanical Composition Chart

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 655 MPa | 95000 psi |

| Yield strength | 415 MPa | 60200 psi |

| Bulk modulus (typical for steel) | 140 GPa | 20300 ksi |

| Shear modulus (typical for steel) | 80 GPa | 11600 ksi |

| Elastic modulus | 190-210 GPa | 27557-30458 ksi |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break (in 50 mm) | 25.70% | 25.70% |

| Hardness, Brinell | 197 | 197 |

| Hardness, Knoop (converted from Brinell hardness) | 219 | 219 |

| Hardness, Rockwell B (converted from Brinell hardness) | 92 | 92 |

| Hardness, Rockwell C (converted from Brinell hardness. Value below normal HRC range, for comparison purposes only) | 13 | 13 |

| Hardness, Vickers (converted from Brinell hardness) | 207 | 207 |

| Machinability (based on AISI 1212 as 100 machinabilities) | 65 | 65 |