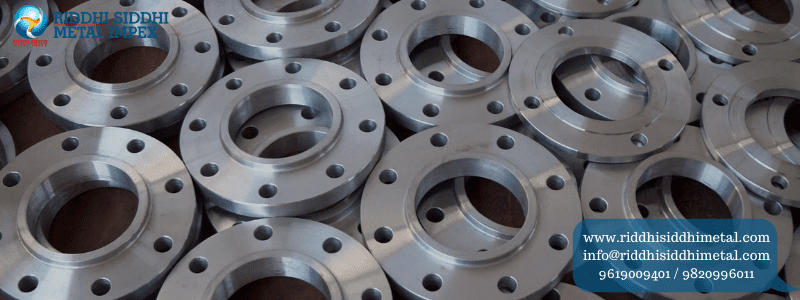

Riddhi Siddhi Metal Impex is one of the leading Molybdenum Alloy Flanges

& Molybdenum Alloy Buttweld Fittings Manufacturer in Mumbai,

India. Our Products have been designed according to the national and

international industry rules by using high-grade raw materials and advanced technology.

Our ASTM

B387 Molybdenum Alloy Buttweld Fittings and other products are subjected to

various quality checks, and then goes for packaging. Riddhi Siddhi Metal Impex is the

world-leading exporter of Molybdenum Alloy Buttweld Fittings. We have a ready

stock of Stainless Steel of different sizes and shapes per the customers’

requirements. We treat our customers as partners by providing them with our products and

solutions.

ASTM B386/ASTM B387 Molybdenum Alloy

Flanges, Molybdenum Buttweld Fittings, ASTM B387 Molybdenum Alloy Tube Fittings &

Fasteners Manufacturer in India

Molybdenum Alloy Flanges are exclusively designed for several

piping applications of various industries. We are also known as one of the Largest

Suppliers of high-quality Molybdenum Alloy Fastener exporter, Molybdenum Flanges

supplier, Molybdenum Elbows Fittings exporter, Molybdenum Alloy Flanges Exporter,

Molybdenum Bolts Nuts Washers, Manufacturer, Molybdenum Alloy Tube Tee supplier, ASTM

B387 Molybdenum Fittings, Molybdenum Alloy Nuts, Alloy Plate Flange, and many

more. Molybdenum Alloy Buttweld Fittings are defined as one of the

essential parts of the Pipe Fitting Industry. We are also known as one of the Largest

Suppliers of Niobium

Buttweld Fittings.

Types of Molybdenum Alloy

Molybdenum

Alloy Grades

| Molybdenum |

ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91, ASTM

B387,

Ferro Molybdenum |

Molybdenum

Alloy Chemical Composition

| Element |

Content (%) |

| Molybdenum, Mo |

100 |

Molybdenum

Alloy Mechanical Properties

| Properties |

Metric |

Imperial |

| Tensile strength (annealed) |

324 MPa |

47000 psi |

| Shear strength (torsional strain rate 0.25/s) |

500 MPa |

72500 psi |

| Compressive yield strength (0.01% yield) |

400 MPa |

58000 psi |

| Modulus of elasticity |

330 GPa |

47900 ksi |

| Modulus of elasticity at elevated temperature

(@2000°C/3630°F) |

160 GPa |

23200 ksi |

| Poissons ratio (calculated) |

0.38 |

0.38 |

| Hardness, Brinell (converted from Vickers for 3000 kg load/10 mm

ball Brinell test. annealed) |

225 |

225 |

| Hardness, Rockwell A (converted from Vickers. annealed) |

60 |

60 |

| Hardness, Rockwell B (converted from Vickers. annealed) |

98 |

98 |

| Hardness, Rockwell C (converted from Vickers. annealed) |

19 |

19 |

| Hardness, Vickers (annealed) |

230 |

230 |

Molybdenum

Alloy Physical Properties

| Properties |

Metric |

Imperial |

| Density |

10.3 g/cm³ |

0.369 lb/in³ |

| Melting point |

2625°C |

4760°F |