Blind Flanges Manufacturers, Suppliers & Stockists in India – Riddhi Siddhi Metal Impex

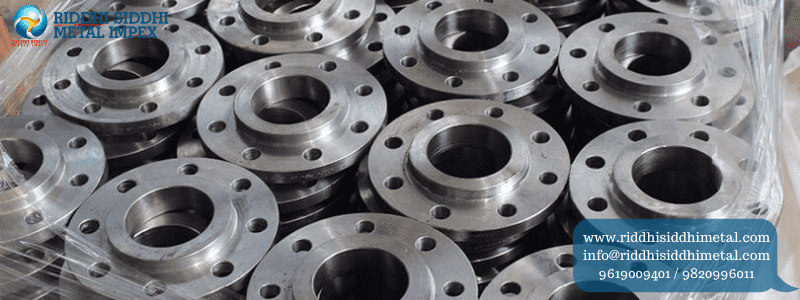

Riddhi Siddhi Metal Impex is one of the leading Blind Flanges Manufacturers in Mumbai, India. The Stainless Steel MSS S 44 has been designed under national and international industry rules using high-grade raw materials and advanced technology. Our ANSI/ASME B16.5 Blind Flanges and other products are subjected to various quality checks, and then goes for packaging. We have a ready stock of different sizes and shapes per the customers’ requirements. These metals are used in Industrial Sectors like Building & Construction Industry, petrochemical, Oil & Gas Industry, and chemical industries. Moreover, Stainless Steel Blind Flanges can be tailored per our client’s requirements.

Stainless Steel Blind Flanges Supplier, Carbon Steel Blind Flanges Stockists, Blind Flanges Dealers, Blind Flanges Exporters in India.

Stainless Steel Blind Flanges are machined with solid forgings. We are also known as one of the Largest Suppliers of high-quality Alloy Steel Blind Plate Flanges, Carbon Steel Blind Flange, and many more. Stainless Steel Blind Flanges are defined as one of the essential parts of the Pipe Fitting Industry. We are also known as one of the Largest Suppliers of Screwed/Threaded Flanges.

Blind Flanges Specification, Grades, Size, & Materials

| ASME B16.5 Blind Flanges Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 | ||

|---|---|---|---|

| Blind Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 | ||

| Blind Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Blind Flange | ||

| Blind Flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Blind Flange | ||

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Blind Flange | ||

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar Blind Flange | ||

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar Blind Flange | ||

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Blind Flange | ||

| Most common types of Blind Flange | Forged / Threaded / Screwed / Plate | ||

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third-Party Inspection Report, etc |

||

| Production technique |

|

||

| Connect Type/ Flanges Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove | ||

| Special design | As per your drawingAS,

ANSI, BS, DIN, and JIS 15 NB (1/2″) to 200 NB (8″) Equal and Reducing Configurations |

||

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI ultrasonic flaw detector, Magnetic particle detector | ||

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine, etc | ||

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS,

AS2129, AWWA, EN, SABS, NFE

etc. Blind Flange: -BS Flanges, EN Flanges, API 6A Flanges, ANSI Flanges, ASME Flanges, DIN Flanges, EN1092-1 Flanges, UNI Flanges, JIS/ KS Flanges, BS4504 Flanges, GB Flanges, AWWA C207 Flanges, GOST Flanges, PSI Flanges

|

||

| Grades | |||

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L | ||

| Super Duplex Steel | S32750 | ||

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. | ||

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 | ||

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. | ||

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 | ||

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI | ||

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L | ||

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G | ||

| Molybdenum | ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91, ASTM B387, Ferro Molybdenum | ||

| Cobalt | Cobalt HS-6, Cobalt HS-4, Cobalt HS-25, Sterlite Grade 1, Sterlite Grade 6, Sterlite Grade 12, Sterlite Grade 21 | ||

| Niobium | ASTM B394, R04200 R04210 | ||

| Nimonic | Nimonic75, Nimonic80, Nimonic85, Nimonic90, Nimonic263, etc | ||

| Tungsten | W1 WAl1, W61, etc, Carbonide Tungsten, Copper Tungsten, Nickel Tungsten | ||

| Nichrome | Nichrome90, Nichrome80, Nichrome80A, Nichrome RW80, Nichrome75, etc | ||

| Magnesium | Magnesium AL017100, AL017140, AL017150, AL017160, AL017200, AL017210, AL017250, etc. | ||

| Tantalum | Tantalum – Grade 1. | ||

| Monel | Monel 400, Monel k500 | ||

| MU-METAL | MU-METAL | ||

| Zirconium | Zirconium 702, Zirconium 705, Zirconium 705, Zirconium-2, Zirconium-4 | ||

| Beryllium Copper | Alloy 25 UNSC17200 | ||

| Aluminium | 1050,1100, 2017, 7150, 7178, 7575, 2050, 7085, 2011 A92011, 2014A A92014, 2024 A92024, 2219, 5052 A95052, 5083 A95083, 5754, 6061 A96061 A86061, 6063, 6082 A96082, 7071 7020, 7050 A97050, 7075 A97075 A87075, 7175 | ||

| Copper Alloys | C 11000, C 10200, C 12200, C 51100, C 51000, C 51900, C 52000, C 52100, C 74500, C 75700, C 75400, C 76400, C 77000, C 21000, C 22000, C 23000, C 24000, C 26000, C 26800, C 27000, C 27200, C 28000 | ||

Materials

| Dimensions | Base Material | Pressure Rating |

|---|---|---|

| ASME B16.5 | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| API 605 | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| ASME B16.47series A & B | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| EN1092-1 | ASTM A182 (Forgings) | PN2.5. PN6. PN10. PN16. PN25. PN40. PN63. PN100. PN160. PN250. PN320. PN400. |

| BS4504 | BS970 (Bar)ASTM A240 (Plate) ASTM A182 (Forgings) | PN2.5. PN6. PN10. PN16. PN25. PN40. PN63. PN100. PN160. |

| BS10 | BS970 (Bar)ASTM A240 (Plate) ASTM A182 (Forgings) |

Types Of Blind Flanges

Other Types Of Stainless Steel Flanges

- Socket Weld Neck Flanges Manufacturers in India

- Slip On Flange Manufacturers in India

- Blind Flanges Manufacturers in India

- Screwed/Threaded Flanges Manufacturers in India

- Long Weld Neck Flanges Manufacturers in India

- Lap Joint Flanges Manufacturers in India

- Spectacle Blind Flange Manufacturers in India

- Ring Type Joint Flange Manufacturers in India

Riddhi Siddhi Metal Impex is the leading Blind Flanges Manufacturers and Suppliers in India.

Riddhi Siddhi Metal Impex is the most trusted Blind Flanges manufacturer & supplier in India. Our High-quality, sensible customer service, and in-house processing capabilities have made us one of the best emerging and leading suppliers in India. We are an ISO 9001:2009 certified company that has been in existence since 2003. ASTM | ASME | ANSI Blind Flanges at Riddhi Siddhi Metal Impex In bears toughness and hardness check before provision it to our purchasers.

Blind Flanges Application & Uses

- Blind Flanges used in Transporting materials

- Stainless Steel Blind Flanges used in the Automotive industry

- Blind Flanges used in Homes and buildings

- Stainless Steel Blind Flanges are used in Sewerage systems and industrial water lines.

- Carbon Steel Blind Flanges are used in heating and air-conditioning equipment.

- Blind Flanges used in Plumbing

- Alloy Blind Flanges used in Food Processing Industry

- Blind Flanges used in the Paper & Pulp Industry

- Blind Flanges used in Food Industry

ASTM / ASME / AISI Class 150 Blind Flanges Dimension & Sizes

| Size in Inch |

Size in mm |

Outer Dia. |

Flange Thick. |

RF Dia. |

RF Height |

PCD | No of Bolts |

Bolt Size UNC |

Machine Bolt Length |

RF Stud Length |

Hole Size | ISO Stud Size |

Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | 400 | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 130 |

| 24 | 600 | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

ASTM / ASME / AISI Blind Flanges Weight Chart

| CLASS | Nominal Pipe Size | Slip-On | Threaded | Socket Weld | Lap Joint | Blind | Weld Neck |

| 150 lb | ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 | |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 | |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 | |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 | |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 | |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 | |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 | |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 | |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 | |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 | |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 | |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 | |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 | |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 | |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 | |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 | |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 | |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 |

Other Related Products

Blind Flanges Packing & Delivery Details:-

- Payment Modes: LC (Letter of Credit), TT (Telegraphic Transfer or Wire Transfer), Cheque, and others

- Packaging: Blind Flanges are packaged with caution and safety so they reach our client’s as good as they would expect. Packaging Charges Extra.

- Port of Dispatch: Mumbai, Kalamboli, or Bhiwandi ports in the Maharashtra state of India.

- Tax: 18% GST

Client Projects for Blind Flanges Supplier in India:-

We regularly supply this product to different cities in India. We have a huge clientele covering more than 55 cities in India and 33 countries worldwide. We are known for Socket Weld Flange Supplier and Exporters.

| Product supplied | City |

| Blind Flanges for Automobile Industry | Mumbai, Maharashtra |

| ARAMCO Flanges supply | Hyderabad, Telangana |

| Stainless Steel Flanges supply for Water Supply System | Banglore, Karnataka |

| Flanges for the Chemical industry | Surat, Gujarat |

Blind Flanges Manufacturers and Suppliers in India- Riddhi Siddhi Metal Impex

Blind Flanges dependability and performance have created Riddhi Siddhi Metal Impex leading suppliers, dealers, manufacturers, and exporters in India. Each month we tend to supply/export Blind Flanges to Indian port around fifty-two containers to completely different customers. We are a Blind Flanges Supplier in Mumbai, Chennai, Surat, New Delhi, Bangalore, and more than 80+ other cities.

| The city we supply Types of Blind Flanges: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Blind Flanges Manufacturers Exporters in India- Riddhi Siddhi Metal Impex

Riddhi Siddhi Metal Impex exports Blind Flanges to UAE, European countries, Africa, Asian countries, and other continents. We have shipments going to various countries every month. With the increasing clientele, we export 3 containers of Blind Flanges to new locations and ports Each month. We are India’s top Manufacturers and have been leading the market for the past few decades.

| Countries we supply and export Types of Blind Flanges worldwide: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |