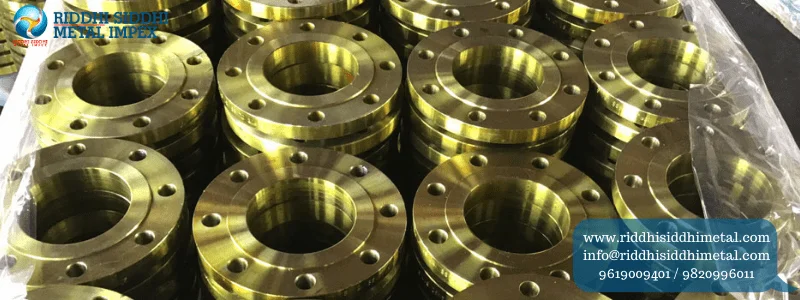

Riddhi Siddhi Metal Impex is one of the leading Copper Alloy Flanges & Copper Buttweld Fittings Manufacturer in Mumbai, India. Our Product has been designed under national and international industry rules using high-grade raw materials and advanced technology. Our ASTM B62 Copper Alloy Flanges and other products are subjected to various quality checks, and then goes for packaging. Riddhi Siddhi Metal Impex is the world-leading exporter of Copper Alloy Flanges and Copper Buttweld Fittings. We have a ready stock of Stainless Steel of different sizes and shapes per the customers’ requirements. We treat our customers as partners by providing them with our products and solutions.

Super Duplex Steel Buttweld Fittings Manufacturer, Super Duplex Steel Flanges Supplier, Super Duplex Steel Gasket Exporter, ASME SA815M Super Duplex Buttweld Fittings Dealer in India

Super Duplex Steel Flanges is exclusively designed for several piping applications of various industries. We are also known as one of the Largest Suppliers of high-quality Super Duplex Steel 2507 Pipe Fittings Manufacturer, Super Duplex Steel Tube Tee supplier, Super Duplex Steel S32750 Fastener, UNS S32760 Super Duplex Lapped joint Flanges, and many more. Super Duplex Steel Flanges are defined as one of the essential parts of the Pipe Fitting Industry. We are also known as one of the Largest Suppliers of Nickel Alloy.

Types of Copper Alloy

ASTM B62 Copper Alloy Grades Chart

Grades: C 11000, C 10200, C 12200, C 51100, C 51000, C 51900, C 52000, C 52100, C 74500, C 75700, C 75400, C 76400, C 77000, C 21000, C 22000, C 23000, C 24000, C 26000, C 26800, C 27000, C 27200, C 28000

Copper Alloy Chemical Composition Chart

| Family | CDA | AMS | UNS | Cu [%] | Sn [%] | Pb [%] | Zn [%] | Ni [%] | Fe [%] | Al [%] | Other [%] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Red brass | 833 | C83300 | 93 | 1.5 | 1.5 | 4 | |||||

| C83400 | 90 | 10 | |||||||||

| 836 | 4855B | C83600 | 85 | 5 | 5 | 5 | |||||

| 838 | C83800 | 83 | 4 | 6 | 7 | ||||||

| Semi-red brass | 844 | C84400 | 81 | 3 | 7 | 9 | |||||

| 845 | C84500 | 78 | 3 | 7 | 12 | ||||||

| 848 | C84800 | 76 | 3 | 6 | 15 | ||||||

| Manganese bronze | C86100 | 67 | 0.5 | 21 | 3 | 5 | Mn 4 | ||||

| 862† | C86200 | 64 | 26 | 3 | 4 | Mn 3 | |||||

| 863† | 4862B | C86300 | 63 | 25 | 3 | 6 | Mn 3 | ||||

| 865 | 4860A | C86500 | 58 | 0.5 | 39.5 | 1 | 1 | Mn 0.25 | |||

| Tin bronze | 903 | C90300 | 88 | 8 | 4 | ||||||

| 905 | 4845D | C90500 | 88 | 10 | 0.3 max | 2 | |||||

| 907 | C90700 | 89 | 11 | 0.5 max | 0.5 max | ||||||

| Leaded tin bronze | 922 | C92200 | 88 | 6 | 1.5 | 4.5 | |||||

| 923 | C92300 | 87 | 8 | 1 max | 4 | ||||||

| 926 | 4846A | C92600 | 87 | 10 | 1 | 2 | |||||

| 927 | C92700 | 88 | 10 | 2 | 0.7 max | ||||||

| High-leaded tin bronze | 932 | C93200 | 83 | 7 | 7 | 3 | |||||

| 934 | C93400 | 84 | 8 | 8 | 0.7 max | ||||||

| 935 | C93500 | 85 | 5 | 9 | 1 | 0.5 max | |||||

| 937 | 4842A | C93700 | 80 | 10 | 10 | 0.7 max | |||||

| 938 | C93800 | 78 | 7 | 15 | 0.75 max | ||||||

| 943 | 4840A | C94300 | 70 | 5 | 25 | 0.7 max | |||||

| Aluminium bronze | 952 | C95200 | 88 | 3 | 9 | ||||||

| 953 | C95200 | 89 | 1 | 10 | |||||||

| 954 | 4870B 4872B |

C95400 | 85 | 4 | 11 | ||||||

| C95410 | 85 | 4 | 11 | Ni 2 | |||||||

| 955 | C95500 | 81 | 4 | 4 | 11 | ||||||

| C95600 | 91 | 7 | Si 2 | ||||||||

| C95700 | 75 | 2 | 3 | 8 | Mn 12 | ||||||

| 958 | C95800 | 81 | 5 | 4 | 9 | Mn 1 | |||||

| Silicon bronze | C87200 | 89 | Si 4 | ||||||||

| C87400 | 83 | 14 | Si 3 | ||||||||

| C87500 | 82 | 14 | Si 4 | ||||||||

| C87600 | 90 | 5.5 | Si 4.5 | ||||||||

| 878 | C87800 | 80 | 14 | Si 4 | |||||||

| C87900 | 65 | 34 | Si 1 | ||||||||

| † Chemical composition may vary to yield mechanical properties | |||||||||||

Copper Alloy Mechanical Composition Chart

| Name | Nominal composition (percentages) | Form and condition | Yield strength (0.2% offset, ksi) | Tensile strength (ksi) | Elongation in 2 inches (percent) | Hardness (Brinell scale) |

|---|---|---|---|---|---|---|

| Copper (ASTM B1, B2, B3, B152, B124, R133) | Cu 99.9 | Annealed | 10 | 32 | 45 | 42 |

|

|

|

Cold-drawn | 40 | 45 | 15 | 90 |

|

|

|

Cold-rolled | 40 | 46 | 5 | 100 |

| Gilding metal (ASTM B36) | Cu 95.0, Zn 5.0 | Cold-rolled | 50 | 56 | 5 | 114 |

| Cartridge brass (ASTM B14, B19, B36, B134, B135) | Cu 70.0, Zn 30.0 | Cold-rolled | 63 | 76 | 8 | 155 |

| Phosphor bronze (ASTM B103, B139, B159) | Cu 89.75, Sn 10.0, P 0.25 | Spring temper | — | 122 | 4 | 241 |

| Yellow or High brass (ASTM B36, B134, B135) | Cu 65.0, Zn 35.0 | Annealed | 18 | 48 | 60 | 55 |

|

|

|

Cold-drawn | 55 | 70 | 15 | 115 |

|

|

|

Cold-rolled (HT) | 60 | 74 | 10 | 180 |

| Manganese bronze (ASTM 138) | Cu 58.5, Zn 39.2, Fe 1.0, Sn 1.0, Mn 0.3 | Annealed | 30 | 60 | 30 | 95 |

|

|

|

Cold-drawn | 50 | 80 | 20 | 180 |

| Naval brass (ASTM B21) | Cu 60.0, Zn 39.25, Sn 0.75 | Annealed | 22 | 56 | 40 | 90 |

|

|

|

Cold-drawn | 40 | 65 | 35 | 150 |

| Muntz metal (ASTM B111) | Cu 60.0, Zn 40.0 | Annealed | 20 | 54 | 45 | 80 |

| Aluminium bronze (ASTM B169 alloy A, B124, B150) | Cu 92.0, Al 8.0 | Annealed | 25 | 70 | 60 | 80 |

|

|

|

Hard | 65 | 105 | 7 | 210 |

| Beryllium copper (ASTM B194, B196, B197) | Cu 97.75, Be 2.0, Co or Ni 0.25 | Annealed, solution-treated | 32 | 70 | 45 | B60 (Rockwell) |

|

|

|

Cold-rolled | 104 | 110 | 5 | B81 (Rockwell) |

| Free-cutting brass | Cu 62.0, Zn 35.5, Pb 2.5 | Cold-drawn | 44 | 70 | 18 | B80 (Rockwell) |

| Nickel silver (ASTM B122) | Cu 65.0, Zn 17.0, Ni 18.0 | Annealed | 25 | 58 | 40 | 70 |

|

|

|

Cold-rolled | 70 | 85 | 4 | 170 |

| Nickel silver (ASTM B149) | Cu 76.5, Ni 12.5, Pb 9.0, Sn 2.0 | Cast | 18 | 35 | 15 | 55 |

| Cupronickel (ASTM B111, B171) | Cu 88.35, Ni 10.0, Fe 1.25, Mn 0.4 | Annealed | 22 | 44 | 45 | – |

|

|

|

Cold-drawn tube | 57 | 60 | 15 | – |

| Cupronickel | Cu 70.0, Ni 30.0 | Wrought | – | – | – | – |

| Ounce metal Copper alloy C83600 (also known as “Red brass” or “composition metal”) (ASTM B62) | Cu 85.0, Zn 5.0, Pb 5.0, Sn 5.0 | Cast | 17 | 37 | 25 | 60 |

| Gunmetal (known as “red brass” in US) | Varies Cu 80-90%, Zn <5%, Sn ~10%, +other elements@ <1% |

Classification of copper and its alloys

| Family | Principal alloying element | UNS numbers |

|---|---|---|

| Copper alloys, brass | Zinc (Zn) | C1xxxx–C4xxxx,C66400–C69800 |

| Phosphor bronze | Tin (Sn) | C5xxxx |

| Aluminium bronzes | Aluminium (Al) | C60600–C64200 |

| Silicon bronzes | Silicon (Si) | C64700–C66100 |

| Cupronickel, nickel silvers | Nickel (Ni) | C7xxxx |