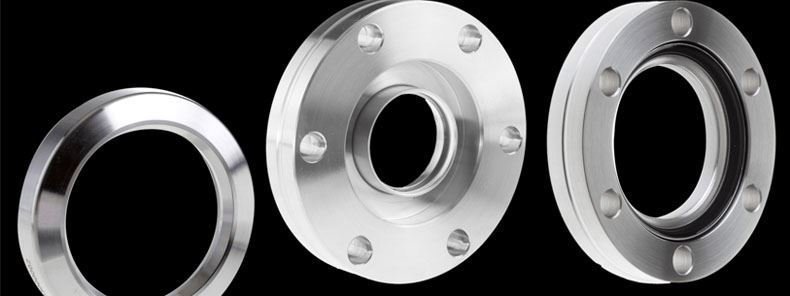

Riddhi Siddhi Metal Impex is a leading SS Flange Manufacturer in Sudan. SS Flanges have been designed under the national and international industry rules using high-grade raw materials and advanced technology. Our High-Quality SS Flanges and other products are subjected to various quality checks, and then goes for packaging. We have a ready stock of SS Flanges of different sizes and shapes per the customers’ requirements. Stainless Steel Flanges can be used as a plate to cover or close a pipe’s termination. A blind flange is what this is called. As a result, SS Flanges are considered important internal components that may be used to support mechanical parts or systems.

Stainless Steel Flanges, SS EIL Approved Flange, IBR Approved, ARAMCO Approved Flanges Manufacturer, Supplier in Sudan

Stainless Steel Flanges are machined with solid forgings. Performance and Dependability have made Riddhi Siddhi Metal Impex the leading Stainless Steel Flanges, SS EIL Approved Flange, IBR Approved, ARAMCO Approved Flanges Stockholder, Manufacturer, Supplier, Importer, and Exporter in Sudan. Our SS EIL Approved Flanges are reputed and well known across the globe for their reliability and quality. We treat our clients as partners by providing them with our products and services. We are also known as one of the Largest Suppliers of Pipe Fitting.

Riddhi Siddhi Metal Impex is India’s most trusted Stainless Steel Flange Manufacturer & supplier in Sudan.

Riddhi Siddhi Metal Impex is India’s most trusted Stainless Steel Flange Manufacturer & supplier in Sudan. Our High-quality Flanges, sensible customer service, and in-house processing capabilities have made us one of the best emerging and leading suppliers for Flanges in Sudan. Riddhi Siddhi Metal Impex is an ISO 9001:2009 certified company that has been in existence since 2003. A flange is a rim (lip) or an external or interior ridge used for strength. Stainless Steel Split Flanges can also join two objects together, such as Stainless Steel Screwed Flanges on the end of a pipe, a steam cylinder, and so on. Pipes with Stainless Steel Slip-On Pipe Flanges are easier to keep together and take apart.

SS Flanges Price List

| SS Pipe Flange Price List |

Stainless Steel Screwed

Flanges Per Unit (IN) |

SS ASTM A182 Flange (Uae Dirham) | SS Flange Material (Saudi Riyal) |

| Flanges Ss A 182 Gr F304/304l Flange Wn 150 Rf 304/304l Ss Ios Bore Item Flange-Weld Neck-Asme Class(35pcs) | 323 | 16.69 | 17.05 |

| SS Seamless Butt-Welded Flange / Fittings (Pipe Fittings) Grade 904l | 1,336 | 69.05 | 70.53 |

| Flanges SS A 182 Gr F304/304l Flange Wn 150 Rf 304/304l Ss Ios Bore Item Flange-Weld Neck-Asme Class(59pcs) | 385 | 19.90 | 20.32 |

| Flange SS Gr Sa182 F316 Ansi B16.5 Dn 20, 300#Sch 40s, Weld Neck Rf (12pcs) | 476 | 24.60 | 25.13 |

| Flanges SS A 182 Gr F304/304l Flange Wn 150 Rf 20b462 40/S Bore Item Flange-Type-Weld Neck (3pcs) | 811 | 41.92 | 42.81 |

| Flange SS Gr Sa182 F316 Ansi B16.5 Dn25,150#Sch10s, Weld Neck Rf (60pcs) | 487 | 25.17 | 25.71 |

ASTM / ASME / AISI Flanges Dimension & Sizes

| FLANGE NPS |

Outside Diameter |

Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | Raised Face Thickness (T) |

Flat Face Thickness (T2) |

Bolt Hole (B) | No. of Bolt Holes |

|---|---|---|---|---|---|---|---|---|

| 1/2″ | 3.50″ | 2.38″ | 1.38″ | .063″ | .44″ | .38″ | .62″ | 4 |

| 3/4″ | 3.88″ | 2.75″ | 1.69″ | .063″ | .50″ | .44″ | .62″ | 4 |

| 1″ | 4.25″ | 3.12″ | 2.00″ | .063″ | .56″ | .50″ | .62″ | 4 |

| 1-1/4″ | 4.62″ | 3.50″ | 2.50″ | .063″ | .62″ | .56″ | .62″ | 4 |

| 1-1/2″ | 5.00″ | 3.88″ | 2.88″ | .063″ | .68″ | .62″ | .62″ | 4 |

| 2″ | 6.00″ | 4.75″ | 3.62″ | .063″ | .75″ | .69″ | .75″ | 4 |

| 2-1/2″ | 7.00″ | 5.50″ | 4.12″ | .063″ | .88″ | .82″ | .75″ | 4 |

| 3″ | 7.50″ | 6.00″ | 5.00″ | .063″ | .94″ | .88″ | .75″ | 4 |

| 3-1/2″ | 8.50″ | 7.00″ | 5.50″ | .063″ | .94″ | .88″ | .75″ | 8 |

| 4″ | 9.00″ | 7.50″ | 6.19″ | .063″ | .94″ | .88″ | .75″ | 8 |

| 5″ | 10.00″ | 8.50″ | 7.31″ | .063″ | .94″ | .88″ | .88″ | 8 |

| 6″ | 11.00″ | 9.50″ | 8.50″ | .063″ | 1.00″ | .94″ | .88″ | 8 |

| 8″ | 13.50″ | 11.75″ | 10.62″ | .063″ | 1.12″ | 1.06″ | .88″ | 8 |

| 10″ | 16.00″ | 14.25″ | 12.75″ | .063″ | 1.19″ | 1.13″ | 1.00″ | 12 |

| 12″ | 19.00″ | 17.00″ | 15.00″ | .063″ | 1.25″ | 1.19″ | 1.00″ | 12 |

| 14″ | 21.00″ | 18.75″ | 16.25″ | .063″ | 1.38″ | 1.32″ | 1.12″ | 12 |

| 16″ | 23.50″ | 21.25″ | 18.50″ | .063″ | 1.44″ | 1.38″ | 1.12″ | 16 |

| 18″ | 25.00″ | 22.75″ | 21.00″ | .063″ | 1.56″ | 1.50″ | 1.25″ | 16 |

| 20″ | 27.50″ | 25.00″ | 23.00″ | .063″ | 1.69″ | 1.63″ | 1.25″ | 20 |

| 22″ | 29.50″ | 27.25″ | 25.25″ | .063″ | 1.81″ | 1.75″ | 1.38″ | 20 |

| 24″ | 32.00″ | 29.50″ | 27.25″ | .063″ | 1.88″ | 1.82″ | 1.38″ | 20 |

ASTM / ASME / AISI Flanges Weight Chart

| Nominal Pipe Size |

“A” (O.D.) |

“B” (Thk.) |

“C” (RF Dia.) |

“D” (B.C.D.) |

# Bolt Holes |

Dia. of Bolt Holes |

Approx. Weight |

| 1/2″ | 3-3/4 | 9/16 | 1-3/8 | 2-5/8 | 4 | 5/8 | 2 |

| 3/4″ | 4-5/8 | 5/8 | 1-11/16 | 3-1/4 | 4 | 3/4 | 3 |

| 1″ | 4-7/8 | 11/16 | 2 | 3-1/2 | 4 | 3/4 | 4 |

| 1-1/4″ | 5-1/4 | 3/4 | 2-1/2 | 3-7/8 | 4 | 3/4 | 6 |

| 1-1/2″ | 6-1/8 | 13/16 | 2-7/8 | 4-1/2 | 4 | 7/8 | 7 |

| 2″ | 6-1/2 | 7/8 | 3-5/8 | 5 | 8 | 3/4 | 8 |

| 2-1/2″ | 7-1/2 | 1 | 4-1/8 | 5-7/8 | 8 | 7/8 | 12 |

| 3″ | 8-1/4 | 1-1/8 | 5 | 6-5/8 | 8 | 7/8 | 16 |

| 3-1/2″ | 9 | 1-3/16 | 5-1/2 | 7-1/4 | 8 | 7/8 | 21 |

| 4″ | 10 | 1-1/4 | 6-3/16 | 7-7/8 | 8 | 7/8 | 28 |

| 5″ | 11 | 1-3/8 | 7-5/16 | 9-1/4 | 8 | 7/8 | 37 |

| 6″ | 12-1/2 | 1-7/16 | 8-1/2 | 10-5/8 | 12 | 7/8 | 48 |

| 8″ | 15 | 1-5/8 | 10-5/8 | 13 | 12 | 1 | 79 |

| 10″ | 17-1/2 | 1-7/8 | 12-3/4 | 15-1/4 | 16 | 1-1/8 | 122 |

| 12″ | 20-1/2 | 2 | 15 | 17-3/4 | 16 | 1-1/4 | 183 |

| 14″ | 23 | 2-1/8 | 16-1/4 | 20-1/4 | 20 | 1-1/4 | 241 |

| 16″ | 25-1/2 | 2-1/4 | 18-1/2 | 22-1/2 | 20 | 1-3/8 | 315 |

| 18″ | 28 | 2-3/8 | 21 | 24-3/4 | 24 | 1-3/8 | 414 |

| 20″ | 30-1/2 | 2-1/2 | 23 | 27 | 24 | 1-3/8 | 515 |

| 24″ | 36 | 2-3/4 | 27-1/4 | 32 | 24 | 1-5/8 | 800 |

| 1/16″ raised face included in flange thickness. | |||||||

SS Flange Pressure Rating

| ASME/ANSI B 16.36 | Welding Neck Flange, Slip-on Flange, Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.5 | Welding Neck Flange, Slip-on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Welding Neck Flange, Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| BS 4504 SEC 3.1 | Welding Neck Flange, Hubbed Slip-on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld-On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641, 2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637, 2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |