Riddhi Siddhi Metal Impex is one of the leading Stainless Steel Forged Fittings Manufacturers in Mumbai, India. The Stainless Steel Forged Fittings we provide have been designed under the national and international industry rules using high-grade raw materials and advanced technology. Our ASME SA182 Stainless Steel Forged Fittings, and other products are subjected to various quality checks, and then goes for packaging. We have a ready stock of Stainless Steel Forged Fittings of different sizes and shapes per the customers’ requirements. These Forged Fittings are used in Industrial Sectors like Building & Construction Industry, petrochemical, Oil & Gas Industry, and chemical industries. Moreover, Forged Fittings can be tailored as per our client’s requirements.

ASME SA182 Stainless Steel Forged Fittings Specification, Grades, Size

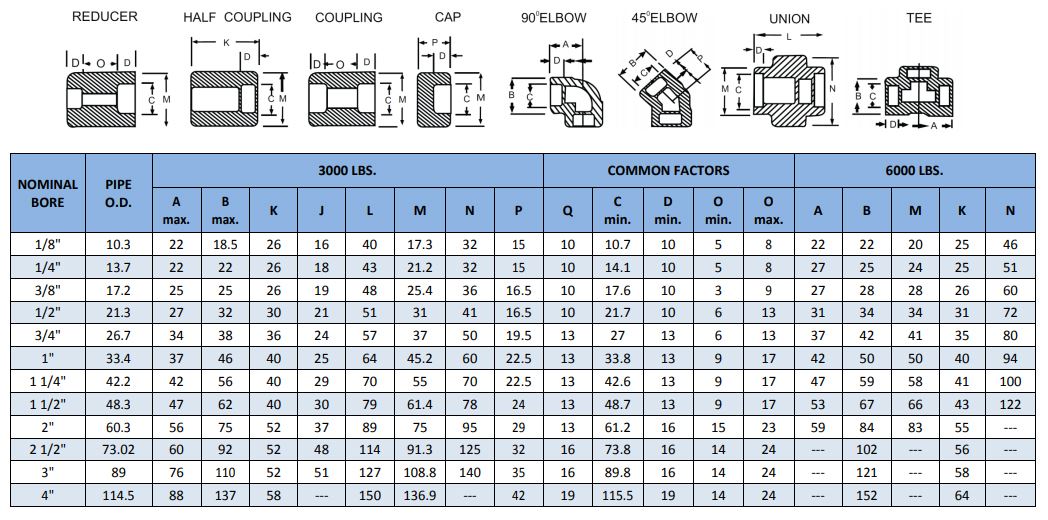

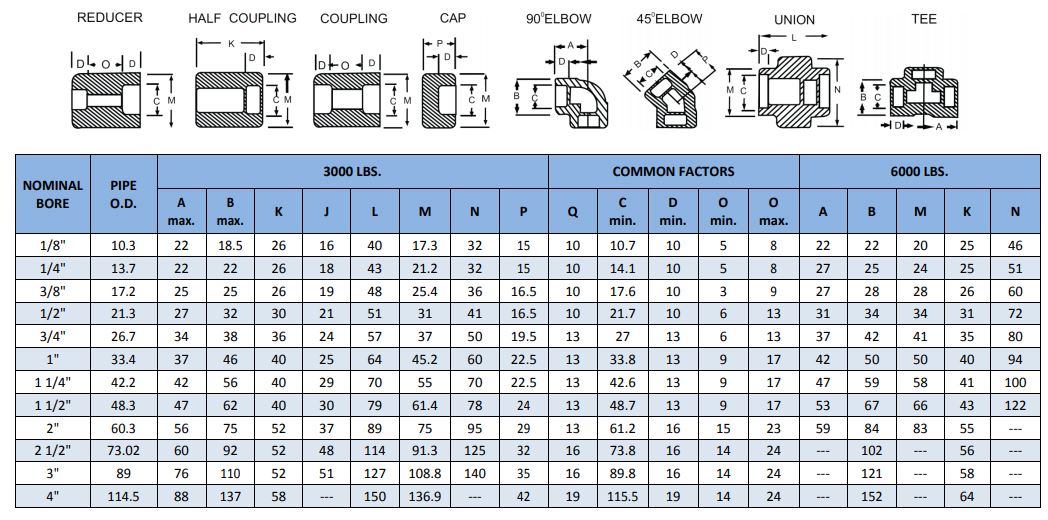

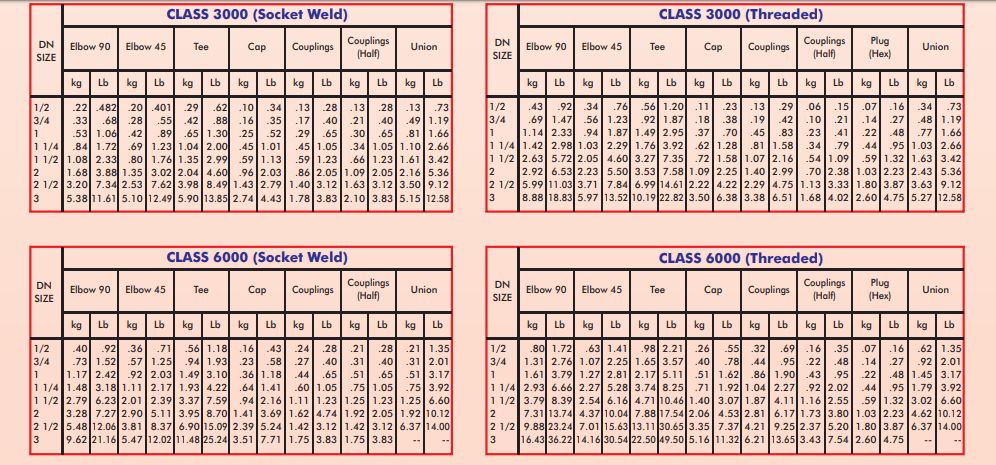

| Forged Pipe Fittings Type | Socket Weld | Threaded |

| Pressure Class | 2000LBS, 3000LBS, 6000LBS, 9000LBS | 2000LBS,3000LBS, 6000LBS, 9000LBS |

| Fittings Form | 90° Elbow, 45° Elbow, Tee, Cross, Full Coupling, Half Coupling, Pipe Cap, Union, Reducer Insert, Boss, Branch Outlet, 90° Elbow Outlet, 45° Lateral Tee, Lateral Outlet, Branch Outlet Butt Weld, 90° Elbow Outlet Butt Weld, Lateral Outlet Butt Weld, Nipple Branch Outlet Butt Weld | 90° Elbow, 45° Elbow, Tee, Cross, Full Coupling, Half Coupling, Reducing Coupling, Pipe Cap, Hex Head Bushing, Hex Head Plug, Square Head Plug, Round Head Plug, Union, Hex Nipple, Street Elbow, Bull Plug, Boss, Swage Nipple, Pipe Nipple, Adapter, Union (Male x Female), Branch Outlet, 90° Elbow Outlet, 45° Lateral Tee, Lateral Outlet, Nipple Branch Outlet |

| Dimension Specifications | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8″~4″ (DN6~DN100) | 1/8″~4″ (DN6~DN100) |

| Thread | —– | ISO, DIN, NPT, BSPT |

SS Forged Pipe Fitting Materials

| Stainless Steel | ASTM A182 F-304/304H/304L/316/316H/316/316Ti, 309, 310, 317L, 321, 347, 904L |

| Duplex and Super-Duplex Steel | ASTM A 182-F51, F53, F55 |

| Nickel | ASTM B 564 N02200, N02201 |

| Inconel | ASTM B 564 N06600, N06601, N06617, ASTM B 564 N07718, ASTM B 564 N06625 |

| Incoloy | ASTM B 564 N08800, N08810, ASTM B 564 N08825, ASTM B 564 N08020 |

| Hastelloy | ASTM B 564 N10276, N06022, ASTM B 564 N10665, ASTM B 564 N06455 |

| Titanium-Commercially | ASTM B 861, 862, 338 Gr.1 R 56250(CP4) |

| Titanium-Pure | Gr.2 R 50400(CP3) Gr.3 R 50550(CP2) Gr.4 R 50700(CP1) Gr.7 R 52400 Gr.11 R 52250 |

| Titanium-Alloys | ASTM B 861, 862, 338 Gr.5 R 56400(6AI-4V) Gr.23 R 56401(6AI-4V-ELI) Gr.12 R 53400 |

| Cupro Nickel | ASTM B 171 C70600(90:10), ASTM B 171 C71500(70:30) |

| Monel | ASTM B 564 N04400 DIN N05500 |

| Carbon Steel | ASTM A 234 WPB IS 1239 PART II |

| Alloys Steel | ASTM A 234 WPB WP5, WP9, WP11, WP12, WP91 |

| Low Temp. CS | ASTM A-420 WPL6 |

| Other Service | Hot Dip Galvanizing, Sand Blasting |

| Test Certificate | Manufacturer Test Certification En 3.1 and 3.2, IBR Test Certificate |

| Specializing In: Large Diameter CS Pipes and Duplex Steel | Inconel®, Incoloy®, Monel®, Hastelloy®, and Duplex® are Registered Trade Marks of their Respective Owners. |