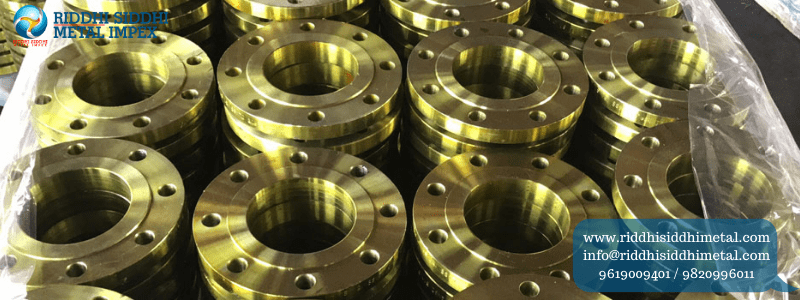

Copper Alloy Flanges, Copper Buttweld Fittings, Copper Alloy Tube Fittings & Fasteners Manufacturer in India – Riddhi siddhi Metal Impex

Riddhi Siddhi Metal Impex is one of the leading Copper Alloy Flanges & Copper Buttweld Fittings Manufacturer in Mumbai, India. Our Product has been designed under national and international industry rules using high-grade raw materials and advanced technology. Our ASTM B62 Copper Alloy Flanges and other products are subjected to various quality checks, and then goes for packaging. Riddhi Siddhi Metal Impex is the world-leading exporter of Copper Alloy Flanges and Copper Buttweld Fittings. We have a ready stock of Stainless Steel of different sizes and shapes per the customers’ requirements. We treat our customers as partners by providing them with our products and solutions.

Copper Alloy Buttweld Fittings Manufacturer, Copper Alloy Flanges Supplier, Copper Alloy Gasket Exporter, ASTM B62 Buttweld Fittings Dealer in India

Copper Alloy Flanges are exclusively designed for several piping applications in various industries. We are also known as one of the Largest Suppliers of high-quality Copper Flanges supplier, Copper Elbows Fittings exporter, Copper Alloy Flanges Exporter, Copper Bolts Nuts Washers, Manufacturer, Copper Alloy Tube Tee supplier, ANSI B16.5 Copper Alloy Reducer, Copper Alloy Nuts, Copper Alloy Plate Flange, Copper Alloy Forged Tube, Copper Bolts Suppliers, and many more. Copper Alloy Flanges & Copper Buttweld Fittings are essential parts of the Pipe Fitting Industry. We are also known as one of the Largest Suppliers of Aluminium Alloy Flanges.

ASTM B62 Copper Alloy Grades Chart

Grades: C 11000, C 10200, C 12200, C 51100, C 51000, C 51900, C 52000, C 52100, C 74500, C 75700, C 75400, C 76400, C 77000, C 21000, C 22000, C 23000, C 24000, C 26000, C 26800, C 27000, C 27200, C 28000

Copper Alloy Chemical Composition Chart

| Family | CDA | AMS | UNS | Cu [%] | Sn [%] | Pb [%] | Zn [%] | Ni [%] | Fe [%] | Al [%] | Other [%] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Red brass | 833 | C83300 | 93 | 1.5 | 1.5 | 4 | |||||

| C83400 | 90 | 10 | |||||||||

| 836 | 4855B | C83600 | 85 | 5 | 5 | 5 | |||||

| 838 | C83800 | 83 | 4 | 6 | 7 | ||||||

| Semi-red brass | 844 | C84400 | 81 | 3 | 7 | 9 | |||||

| 845 | C84500 | 78 | 3 | 7 | 12 | ||||||

| 848 | C84800 | 76 | 3 | 6 | 15 | ||||||

| Manganese bronze | C86100 | 67 | 0.5 | 21 | 3 | 5 | Mn 4 | ||||

| 862† | C86200 | 64 | 26 | 3 | 4 | Mn 3 | |||||

| 863† | 4862B | C86300 | 63 | 25 | 3 | 6 | Mn 3 | ||||

| 865 | 4860A | C86500 | 58 | 0.5 | 39.5 | 1 | 1 | Mn 0.25 | |||

| Tin bronze | 903 | C90300 | 88 | 8 | 4 | ||||||

| 905 | 4845D | C90500 | 88 | 10 | 0.3 max | 2 | |||||

| 907 | C90700 | 89 | 11 | 0.5 max | 0.5 max | ||||||

| Leaded tin bronze | 922 | C92200 | 88 | 6 | 1.5 | 4.5 | |||||

| 923 | C92300 | 87 | 8 | 1 max | 4 | ||||||

| 926 | 4846A | C92600 | 87 | 10 | 1 | 2 | |||||

| 927 | C92700 | 88 | 10 | 2 | 0.7 max | ||||||

| High-leaded tin bronze | 932 | C93200 | 83 | 7 | 7 | 3 | |||||

| 934 | C93400 | 84 | 8 | 8 | 0.7 max | ||||||

| 935 | C93500 | 85 | 5 | 9 | 1 | 0.5 max | |||||

| 937 | 4842A | C93700 | 80 | 10 | 10 | 0.7 max | |||||

| 938 | C93800 | 78 | 7 | 15 | 0.75 max | ||||||

| 943 | 4840A | C94300 | 70 | 5 | 25 | 0.7 max | |||||

| Aluminium bronze | 952 | C95200 | 88 | 3 | 9 | ||||||

| 953 | C95200 | 89 | 1 | 10 | |||||||

| 954 | 4870B 4872B |

C95400 | 85 | 4 | 11 | ||||||

| C95410 | 85 | 4 | 11 | Ni 2 | |||||||

| 955 | C95500 | 81 | 4 | 4 | 11 | ||||||

| C95600 | 91 | 7 | Si 2 | ||||||||

| C95700 | 75 | 2 | 3 | 8 | Mn 12 | ||||||

| 958 | C95800 | 81 | 5 | 4 | 9 | Mn 1 | |||||

| Silicon bronze | C87200 | 89 | Si 4 | ||||||||

| C87400 | 83 | 14 | Si 3 | ||||||||

| C87500 | 82 | 14 | Si 4 | ||||||||

| C87600 | 90 | 5.5 | Si 4.5 | ||||||||

| 878 | C87800 | 80 | 14 | Si 4 | |||||||

| C87900 | 65 | 34 | Si 1 | ||||||||

| † Chemical composition may vary to yield mechanical properties | |||||||||||

Copper Alloy Mechanical Composition Chart

| Name | Nominal composition (percentages) | Form and condition | Yield strength (0.2% offset, ksi) | Tensile strength (ksi) | Elongation in 2 inches (percent) | Hardness (Brinell scale) |

|---|---|---|---|---|---|---|

| Copper (ASTM B1, B2, B3, B152, B124, R133) | Cu 99.9 | Annealed | 10 | 32 | 45 | 42 |

| Cold-drawn | 40 | 45 | 15 | 90 | ||

| Cold-rolled | 40 | 46 | 5 | 100 | ||

| Gilding metal (ASTM B36) | Cu 95.0, Zn 5.0 | Cold-rolled | 50 | 56 | 5 | 114 |

| Cartridge brass (ASTM B14, B19, B36, B134, B135) | Cu 70.0, Zn 30.0 | Cold-rolled | 63 | 76 | 8 | 155 |

| Phosphor bronze (ASTM B103, B139, B159) | Cu 89.75, Sn 10.0, P 0.25 | Spring temper | — | 122 | 4 | 241 |

| Yellow or High brass (ASTM B36, B134, B135) | Cu 65.0, Zn 35.0 | Annealed | 18 | 48 | 60 | 55 |

| Cold-drawn | 55 | 70 | 15 | 115 | ||

| Cold-rolled (HT) | 60 | 74 | 10 | 180 | ||

| Manganese bronze (ASTM 138) | Cu 58.5, Zn 39.2, Fe 1.0, Sn 1.0, Mn 0.3 | Annealed | 30 | 60 | 30 | 95 |

| Cold-drawn | 50 | 80 | 20 | 180 | ||

| Naval brass (ASTM B21) | Cu 60.0, Zn 39.25, Sn 0.75 | Annealed | 22 | 56 | 40 | 90 |

| Cold-drawn | 40 | 65 | 35 | 150 | ||

| Muntz metal (ASTM B111) | Cu 60.0, Zn 40.0 | Annealed | 20 | 54 | 45 | 80 |

| Aluminium bronze (ASTM B169 alloy A, B124, B150) | Cu 92.0, Al 8.0 | Annealed | 25 | 70 | 60 | 80 |

| Hard | 65 | 105 | 7 | 210 | ||

| Beryllium copper (ASTM B194, B196, B197) | Cu 97.75, Be 2.0, Co or Ni 0.25 | Annealed, solution-treated | 32 | 70 | 45 | B60 (Rockwell) |

| Cold-rolled | 104 | 110 | 5 | B81 (Rockwell) | ||

| Free-cutting brass | Cu 62.0, Zn 35.5, Pb 2.5 | Cold-drawn | 44 | 70 | 18 | B80 (Rockwell) |

| Nickel silver (ASTM B122) | Cu 65.0, Zn 17.0, Ni 18.0 | Annealed | 25 | 58 | 40 | 70 |

| Cold-rolled | 70 | 85 | 4 | 170 | ||

| Nickel silver (ASTM B149) | Cu 76.5, Ni 12.5, Pb 9.0, Sn 2.0 | Cast | 18 | 35 | 15 | 55 |

| Cupronickel (ASTM B111, B171) | Cu 88.35, Ni 10.0, Fe 1.25, Mn 0.4 | Annealed | 22 | 44 | 45 | – |

| Cold-drawn tube | 57 | 60 | 15 | – | ||

| Cupronickel | Cu 70.0, Ni 30.0 | Wrought | – | – | – | – |

| Ounce metal Copper alloy C83600 (also known as “Red brass” or “composition metal”) (ASTM B62) | Cu 85.0, Zn 5.0, Pb 5.0, Sn 5.0 | Cast | 17 | 37 | 25 | 60 |

| Gunmetal (known as “red brass” in US) | Varies Cu 80-90%, Zn <5%, Sn ~10%, +other elements@ <1% |

Classification of copper and its alloys

| Family | Principal alloying element | UNS numbers |

|---|---|---|

| Copper alloys, brass | Zinc (Zn) | C1xxxx–C4xxxx,C66400–C69800 |

| Phosphor bronze | Tin (Sn) | C5xxxx |

| Aluminium bronzes | Aluminium (Al) | C60600–C64200 |

| Silicon bronzes | Silicon (Si) | C64700–C66100 |

| Cupronickel, nickel silvers | Nickel (Ni) | C7xxxx |

Copper Alloy Material Applications & Uses

- Copper Alloy Flanges used in Refineries

- Copper Alloy Buttweld Fittings used in Power Plant

- Copper Alloy Fastener used in Sewerage systems and industrial water lines.

- Copper Alloy Buttweld Fittings Slotted used in heating and air-conditioning equipment.

- Copper Alloy Tube Fittings used in Steel Plants

- Copper Alloy Valves used in Instrumentation systems

- Copper Alloy Flanges Plain used in Paper & Pulp Industry

- Copper Alloy Fittings used in Food Industry

- Copper Alloy Reducer & Expander used in Liquid petroleum gas processing plant

Client’s Project of Copper Alloy Flanges

we regularly supply this product to different cities in India. We have a vast clientele covering more than 55 cities in India and 33 countries worldwide. We are known as Copper Alloy Gaskets Supplier and Exporters.

| Product supplied | City |

|---|---|

| Copper Alloy Flanges for Oil and gas industry | Bareilly, Uttar Pradesh |

| Copper Alloy Fittings supplied to the Pharmaceutical processing industry | Mumbai, Maharashtra |

| Copper Alloy Tube Fittings supply for Piping | Srinagar, Jammu, and Kashmir |

| Copper Alloy Fastener given to industry | Raipur, Chhattisgarh |

ADDITIONAL INFORMATION:

Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer), Other

Port of Dispatch: Mumbai OR KALAMBOLI, India

Packaging Details: Fitting are given marking, painted with black japan or black Board (Mat Finish) & will be packed in a bagging bag with stickers written with size, grade & quantity.

Copper Alloy Flanges, Buttweld Fittings, Copper Alloy Fastener, Tube Fittings Manufacturers Exporters in India- Riddhi Siddhi Metal Impex

Copper Alloy Flanges, Buttweld Fitting’s dependability, and performance have created Riddhi Siddhi Metal Impex leading suppliers, dealers, manufacturers, and exporters of ASME B16.5 Copper Flanges manufacturer in India. Each month we tend to supply/export Fastener to Indian port around fifty-two containers to completely different customers. Riddhi Siddhi Metal Impex are Copper Alloy Fittings Supplier in Mumbai, Chennai, Surat, New Delhi, Bangalore, and more than 80+ other cities.

| Manufacturers Suppliers In India: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | ||||

Copper Alloy Flanges, Copper Buttweld Fittings, Fastener, Tube Fittings Manufacturers Exporters in Countries- Riddhi Siddhi Metal Impex

Riddhi Siddhi Metal Impex exports Copper Alloy Fittings to UAE, European countries, Africa, Asian countries, and other continents. We have shipments going to various countries every month. With the increasing clientele, we export 3 containers of ASME B16.9 Copper Flanges to new locations and ports Each month. We are India’s leading Types of Copper Alloy Fastener, Tube fittings Manufacturers and have been leading the market for the past few decades.

| Countries we supply and export Products of Copper Alloy worldwide: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |